Product Description:

| Name | Scratch Voucher Card |

| Card Material | Coated Paper |

| Card Surface | Glossy/Matte finish |

| Physical Dimension | 85.5*54*350gsm or customized |

| Card Weight | 5.5g+/-0.5g |

| Available Printing Method | Offset/Silkscreen/Digital printing/UV Printing |

| Printing Color | Can be printed in 1 to full color on both sides, and also Pan tone colors or silk screen colors |

| Paper thickness | 200gsm,250gsm,300gsm,350gsm,400gsm |

| Craftwork | Full color printing /Pan tone color printing (Craftwork can be in PDF, AI,PSD, CAD file) |

| Scratch panel(Labeling or hot stamping panel) | |

| Bar code: CODE128,CODE39, EAN8,EAN13 etc. | |

| Hot stamping gold/silver foil color,hologram | |

| Numbers ink jet or UV printing,bar code,QR code printing | |

| Pack with Opp bag and in train | |

| Packing & dimension | 1. Standard export packing: 250pcs/box, 5000pcs/Ctn. |

| 2. G.W./N.W.: 25KG/24KG | |

| 3. Size of carton: 48*23*30cm | |

| 4. Packing way can according to your request | |

| 5. If make sample according to your design, then you will be requested to pay sample charge. | |

| 6. The sample is free If just send sample card we made before for you to test the quality. | |

| Certificate& MOQ | ISO 9001:2000, CE |

| ISO7810 | |

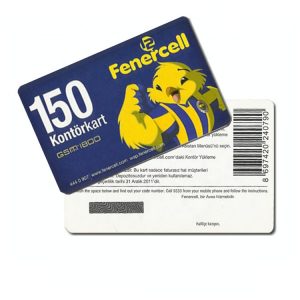

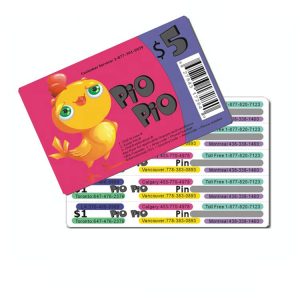

| Paper scratch cards, recharge scratch card,prepaid card | |

| MOQ:5000PCS/Design |

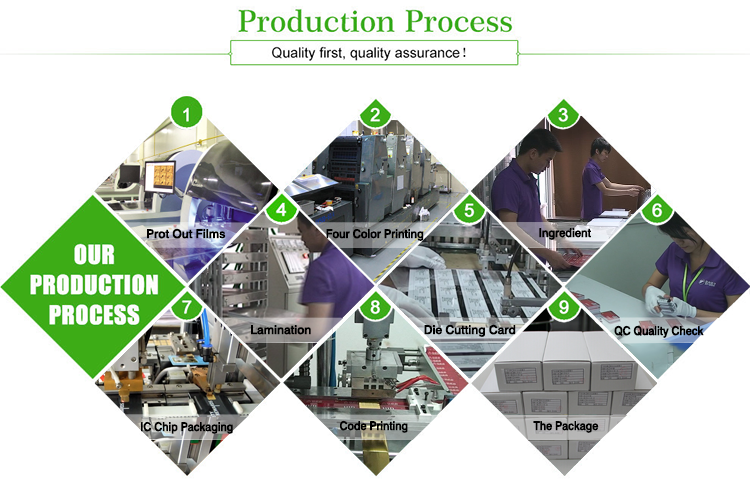

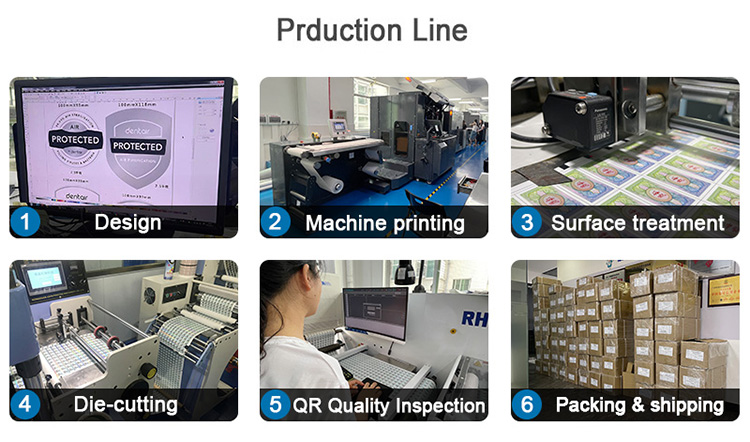

Scratch card production process:

Make

The production of scratch cards is much more difficult than ordinary printed matter, and they are generally designed and produced by professional anti-counterfeiting companies or professional printing factories.

The quality of scratch cards has the following requirements:

- The correctness of the content

The content of the scratch card must be complete and accurate. If it is a scratch card, the prize information, the way of redemption, the activity time, and the validity description should be specified in detail;

- Good printing quality

The scratch card printing is correct and exquisite, and the printing quality is also part of the product image displayed. The printing should meet the quality requirements of the printed matter;

- Appropriate scratching

The scratch card has important information or awards under its scratch coating, so the scratching performance of the coating is an important manifestation of the quality of the scratch card. It should be ensured that it is easy to scratch, but not too easy to scratch. If it is easy to scratch, the scratch card will be easily worn off the scratch layer during production and circulation, thus affecting its use;

- Effective anti-counterfeiting measures

In the design and production of scratch cards, its anti-counterfeiting performance should be fully considered, and the anti-counterfeiting measures adopted should be able to effectively prevent others from being very difficult to forge in batches within a certain period of time.

Craft

- The scratch card can be designed according to the material provided by the customer, or the design draft can be provided by the customer.

- The thickness of the scratch card is 300 grams, 350 grams, 400 grams, and can also be made into other thicknesses.

- The standard size of the scratch card is 85.5mm X 54mm with rounded corners. Other sizes can also be made.

- Scratch cards can be printed on one or both sides, using silk printing or offset printing (CMYK four-color printing) printing method.

- Different numbers, PIN codes or texts can be sprayed on each scratch card.

- The scratch card can be added with a signature strip or writing board (an area where you can write by hand).

- Scratch cards can be equipped with low-density or high-density magnetic strips (three-track magnetic strips) according to customer requirements.

- The scratch card can be embossed, and the embossed code can be hot stamped or silver.

- Round holes or strip holes can be punched in the scratch card.

- You can print the code on the scratch card and apply the scratch bar (usually used for recharge cards\phone cards\lottery cards, etc.).

- Scratch cards can be marked with various types of barcodes.

- Scratch card numbers can be arranged in order, or personalized and irregular numbers can be used.

- The scratch card can be made into square, round and any other irregular shapes.

- The background color of the scratch card can be made into imitation gold or imitation silver.

- You can burn gold or silver on the scratch card.

- The surface of the scratch card can be made into matte or smooth or sub-surface effect.

- The scratch card can be made of white PVC material, frosted transparent material or completely transparent transparent material.

- The printing of color scratch-off ink has a certain degree of difficulty, and cards from European and American countries are common.

Four major differences:

- The second-generation scratch card is precisely controlled to each card through variable data control. Simply put, the issuer can choose to invest in different awards and quantities, and each promotion can be accurately positioned. There is no need to worry about the operator being suspected of cheating;

- Errors can be traced to all links of production to avoid counterfeiting or greater losses;

- A lottery with multiple chances can be achieved with one scratch card;

- It can be achieved that the quantity of each box and each package is absolutely consistent, and there will be no more or less cases.

These are things that the first generation of scratch cards cannot do. Ordinary printing factories cannot do it. The average distribution of each award and the precise control of the award are impossible. Most companies have begun to use the second-generation scratch card, and only professional scratch card manufacturers have the ability to produce it.

Because ordinary printing plants have different equipment, they cannot achieve the precise control of the second-generation scratch cards.