In the business card production process, common business card printing processes include round corners, hot stamping, UV, embossing, and dumb film coating etc. The following is an introduction to various processes:

1. Cutting process

What is the right angle business card printing process?

Generally, business cards are cut without craftsmanship, that is, the edges are right-angled. Of course, you can cut it into rounded corners.

What is the round corner business card printing process?

The edges are rounded, and the rounded corners make the business card more beautiful. Rounded corners are one of the commonly used processing methods to beautify the overall visual sense of business cards.

Cut fillet: cut by a fillet machine, and the radius of the fillet is fixed. The cut rounded corners are slightly burrs, which are only for business cards to be beautiful and not suitable for functional rounded corners.

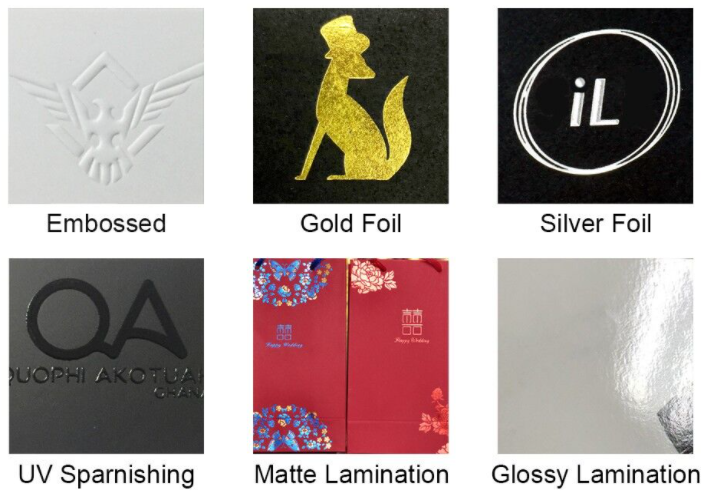

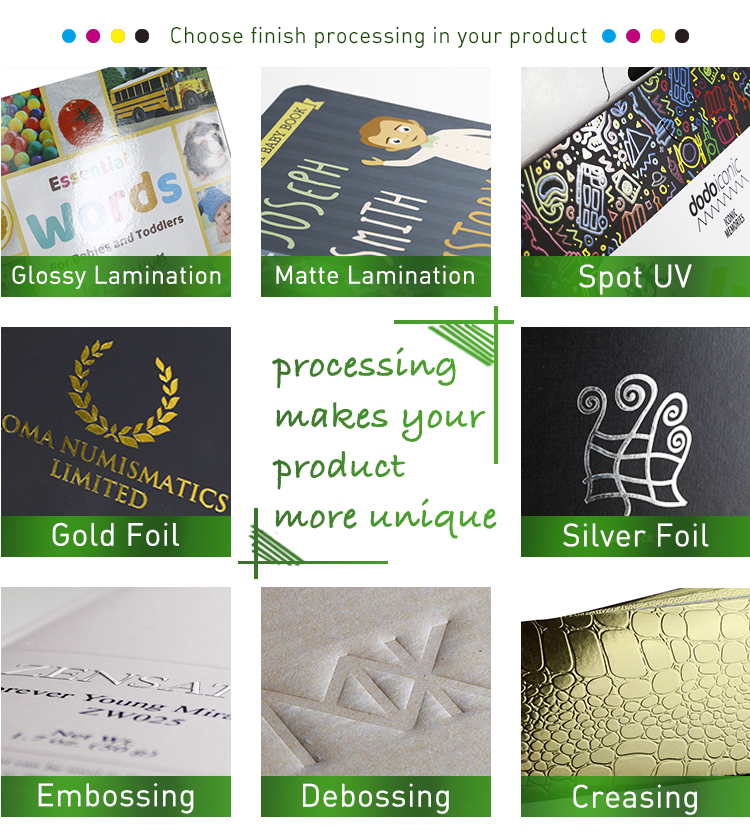

2. Laminating process

The plastic film is covered on the surface of the printed matter, and the adhesive is heated and pressurized to bond them together to form a paper-plastic printed matter. The hand-feel and glossiness of the printed matter covered by the film are better.

Laminating film is divided into light film and dumb film. Of course you can also leave it uncoated.

What is the dumb film business card printing process?

The surface of the product covered with matte film is non-reflective and elegant, and is mostly used for image printing.

What is the printing process of glazing film business card?

The surface of the light-coated product reflects light.

3, UV printing process

UV is the abbreviation, “UV transparent oil” is the full name, which means that the ink can be dried and cured by ultraviolet radiation. UV is usually a silk screen printing process, and now there is also offset printing UV.

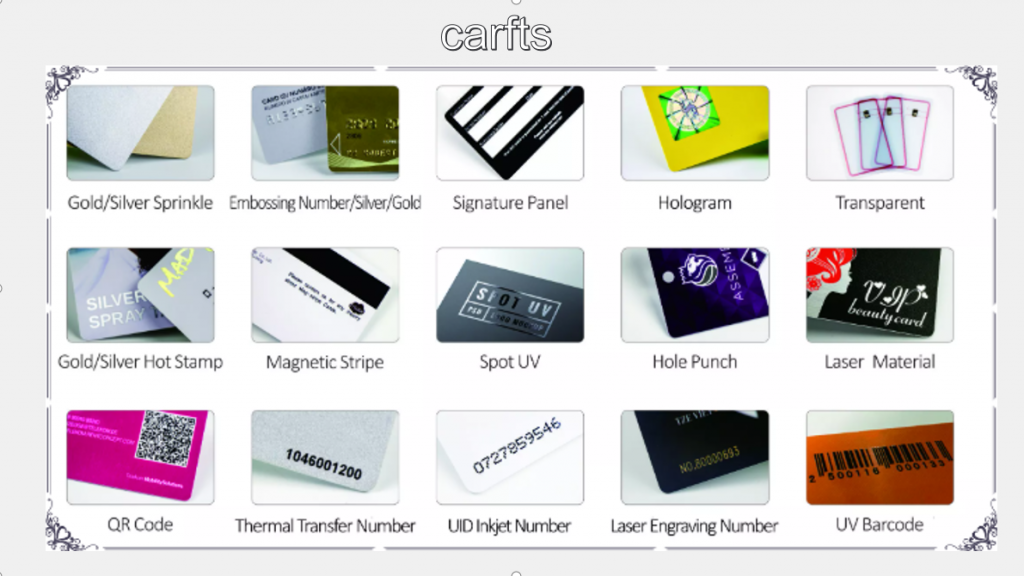

4, bronzing, hot silver technology

Hot stamping: The scientific name is hot press transfer printing, or hot pad printing for short, commonly known as hot stamping and silver hot stamping. In contrast, there is a cold pad printing.

The hot stamping and silver hot stamping process mainly uses a certain pressure and temperature, using the template installed on the hot stamping machine, so that the printed matter and the hot stamping plate are combined in a short time, and the metal foil or color pigment foil is in accordance with the graphic requirements of the hot stamping template. The process of transferring to the surface of the scalded material. Since bronzing is mainly made of gold and silver, it is also often called bronzing. This technology is an important process to increase the visual effects and grades of labels, trademarks, cigarette packs, wine packs and various high-end packaging boxes. With metallic luster and magnificence, it creates a strong contrast in the printed picture.

5, embossing printing process

Embossing and embossing: The scientific name is embossing. It is a process of forming a pattern by pressure to cause local changes to the substrate. The metal plate is corroded and becomes a pressing plate and a base plate for pressing. Divided into two kinds of cheap ordinary corrosion edition and expensive laser engraving edition.

Embossing: Using a convex template (male template) to emboss a three-dimensional relief-like pattern on the surface of the printed matter through pressure (the printed matter is partially convex to make it three-dimensional and cause visual impact), which is called embossing.

Concave: Use the concave template (female template) to emboss the surface of the printed matter into a relief-like pattern with a sense of depression (the printed matter is partially recessed to make it three-dimensional and cause visual impact) through the action of pressure, which is called concavity.

6, punch

Use related equipment to form holes on the printed matter through pressure to facilitate binding or other processes. The common ones are square holes and round holes. Punching can make the printed matter easy to bind, or perform other processes such as stringing. Mostly used for hang tags, document binding, etc.

Punching holes in the required positions is suitable for small quantities. For large quantities of holes, it is recommended to make holes in a die; currently available diameters are 3, 6, 8mm.

7, rolling line

Folding card rolling line: Fold a large printed matter to form an exquisite folding page, which enhances readability and aesthetics. Some of the more exquisite half-folding business cards actually use the rolling process, but some need to be folded by themselves.